Circularity

Plastic is essential to building a circular economy—one where recyclable and reusable materials are recovered, not discarded, and their value is fully realized. Thanks to increasingly sophisticated recycling technologies, plastics can now be transformed into high-quality, purified materials, enhancing circularity and reducing the need to extract new resources from the planet. Global plastics circularity investments are surging. From 2018 to 2023, global investments in plastics circularity totaled $190 billion and averaged $32 billion per year, with more than half invested in North America.1https://www.packagingdive.com/news/plastics-circularity-data-investments-recycling/724764/

Expanding recycling facilities is essential to building a stronger circular economy. As demand for recycled plastic content grows, so must our capacity to collect, recover, and process post-consumer plastics. Increasing recycling infrastructure keeps valuable materials circulating in the economy and out of landfills—while also creating new sustainability jobs that support communities and the environment.

Investments in circularity through recycling infrastructure could create 1 million jobs by 2030. The World Economic Forum sees the circular economy as a major job creator globally, with millions of positions anticipated as companies adopt more efficient resource use and recycling-based manufacturing.2 https://www.weforum.org/stories/2019/10/heres-how-a-circular-economy-could-change-the-world-by-2030/ The UN Conference on Trade and Development echoes this potential, projecting that shifting to a circular economy worldwide could create substantial employment opportunities while also tackling key environmental issues. This approach focuses on keeping materials in use longer, which reduces waste and supports sustainable growth across industries.3https://unctad.org/news/riding-circular-wave-entrepreneurs-tackle-waste-crisis-redefine-economies

Material Use

Feedstocks are the raw materials required for plastics production. These can be fossil or bio-sourced, or made with recycled content. Innovative materials enhance the sustainability footprints of the final product.

Fossil-based & sustainable extraction

The plastics industry is continuously innovating to produce more materials to enhance sustainability.

Fossil-Based Plastics

For plastic products made from fossil sources, there are several opportunities to improve up-stream sustainability by improving energy efficiency, promoting worker safety, and reducing methane emissions and natural gas flaring.

Biobased Bioplastics

Biobased feedstocks can capture atmospheric carbon, sequestering them into plastic products that should then be preferably recycled in some way or landfilled. Companies interested in using more biobased bioplastics can explore either drop-in replacements of common commodity polymers or explore new polymers that have additional functions.

Use of Recycled Content

When recycled content is used in the production of new products, this is where the loop for recyclable plastics closes. Post consumer recycled content is material that has been used by a consumer, disposed of, and collected to be reprocessed into a new product. Many are choosing to certify their recycled content through programs such as APR PCR Certification or ISCC+ to ensure transparency and accuracy of the recycled content being used.

Post industrial recycled content, also known as pre-consumer recycled content, is material that has been processed, but has not yet reached the consumer. PIR is an incredibly valuable feedstock in sustainable plastic production as its consistency, high quality, and low contamination helps to keep essential properties of products (durability, color, etc.) while allowing a high recycled content percentage.

The plastics industry is constantly evolving and innovating to make their materials more effective and efficient. Lightweighting is one option for accomplishing the same functionality with less material. This can be done to a certain extent before properties of product performance are lost.

Other options could include making mono-material products, i.e., product with one polymer use for all components. This can make the product easier to recycle as one unit. Again, functionality is priority and mono-material products are not always possible to be made while keeping the intended function of the product or packaging. There are many opportunities like this to design products to be more easily recycled through our current recycling streams.4https://plasticsrecycling.org/apr-design-hub/apr-design-guide-overview/

Products can also be designed to be compostable. A compostable plastic is one that is capable of undergoing biodegradation during composting to yield CO2, water, inorganic compounds, and biomass at a rate consistent with other known compostable materials (such as food waste) and leave no visible, distinguishable, or toxic residue. Products must meet an internationally accepted compostability standards and be certified as compostable by a 3rd party certification body to be deemed as such.5https://bpiworld.org/

Reusability is another avenue for circularity. Reuse systems are emerging as potential alternatives for single-use applications where durable plastic products can further contribute to a lower overall environmental footprint in these applications.6chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://sustainablepackaging.org/wp-content/uploads/2022/04/Guidance-for-Reusable-Packaging.pdf

Recycling

After the MRF, plastics are bought by re-processing facilities that recycle the used plastic products into pellets that can be made into new products. There are multiple types of recycling to be aware of.

Mechanical Recycling is a method of recovering plastic waste by using mechanical processes such as sorting, washing, drying, grinding, re-granulating, and compounding. Due to its efficient use of energy, mechanical recycling is often chosen first for handling sorted recycling streams.

Did you know?

Packaging, water bottles, building materials, bike helmets, and more can all be made from recycled plastic.

Advanced Recycling

As we move toward a circular economy, there is greater demand to increase plastic recycling as well as recycled content in products. Advanced recycling is a necessary and essential complement to mechanical recycling to ensure that plastics stay out of the environment, while also creating new products and economic growth opportunities that benefit society.

Advanced recycling is a process that encompasses any compositional transformation technology to convert plastics into a purified form or a feedstock that can be used in the production of new polymers, monomers, intermediates, or other materials. It is also known as chemical, molecular, tertiary, or feedstock recycling. Examples include but are not limited to depolymerization, purification, solvent extraction, gasification, and pyrolysis.

While mechanical recycling uses physical processes such as grinding, washing, separating, and compounding in which polymers remain intact, advanced recycling typically alters the chemical structure of plastics, by methods such as dissolving with chemicals or using heat to break them down into original components. Advanced recycling produces materials that are indistinguishable from virgin plastic so they can be used to make a wide range of new products. Advanced recycling is typically broken down into three general categories: purification, depolymerization, and conversion.

Environmental Benefits

In addition to diverting plastics from landfills and ensuring that plastics stay out of the environment, advanced technologies are more environmentally beneficial than the production of virgin plastic from fossil fuels from an emissions standpoint. According to a 2021 report from Closed Loop Partners10 https://www.closedlooppartners.com/wp-content/uploads/2021/11/AR-report-V23_final7.pdf, purification, depolymerization (decomposition), and conversion technologies require less energy, less water and emit fewer greenhouse gases compared to the production of virgin plastics production. These technologies can also help mitigate climate change as they displace the use of virgin plastics and keep valuable materials in circularity.

Economic Opportunity

In a 2021 report11https://www.closedlooppartners.com/wp-content/uploads/2021/11/AR-report-V23_final7.pdf , investment firm Closed Loop Partners found that advanced recycling could yield up to $970 million in potential revenue based on demand for advanced recycling products and double the amount of plastic packaging recycled in 2019. The development of advanced plastic recycling and recovery facilities also have the potential to support nearly 40,000 new jobs in the United States alone. Companies already purchasing the products from advanced recycling or that have announced agreements to do so include Gatorade, H&M, L’Oréal, Procter & Gamble, PepsiCo, and Unilever. Just in the last few years, several industry members have also announced new investments in advanced recycling facilities12https://corporate.exxonmobil.com/news/news-releases/2024/1121_exxonmobil-invests-200m-to-expand-advanced-recycling-in-texas, like Exxon’s expanded capacity in Texas, to ensure that all plastic can and is recycled.

Did you know?

Colored bottles can be broken down and used to make clear PET bottles.

Keeping all plastic resin out of the natural environment is a priority. Operation Clean Sweep equips plastic resin handlers with the tools they need to minimize the risk of resin spills during operations and to recover resin effectively if a release occurs. Industry has developed a multitude of innovative technologies to support resin recovery and remediation to be captured and in many instances, recycled.

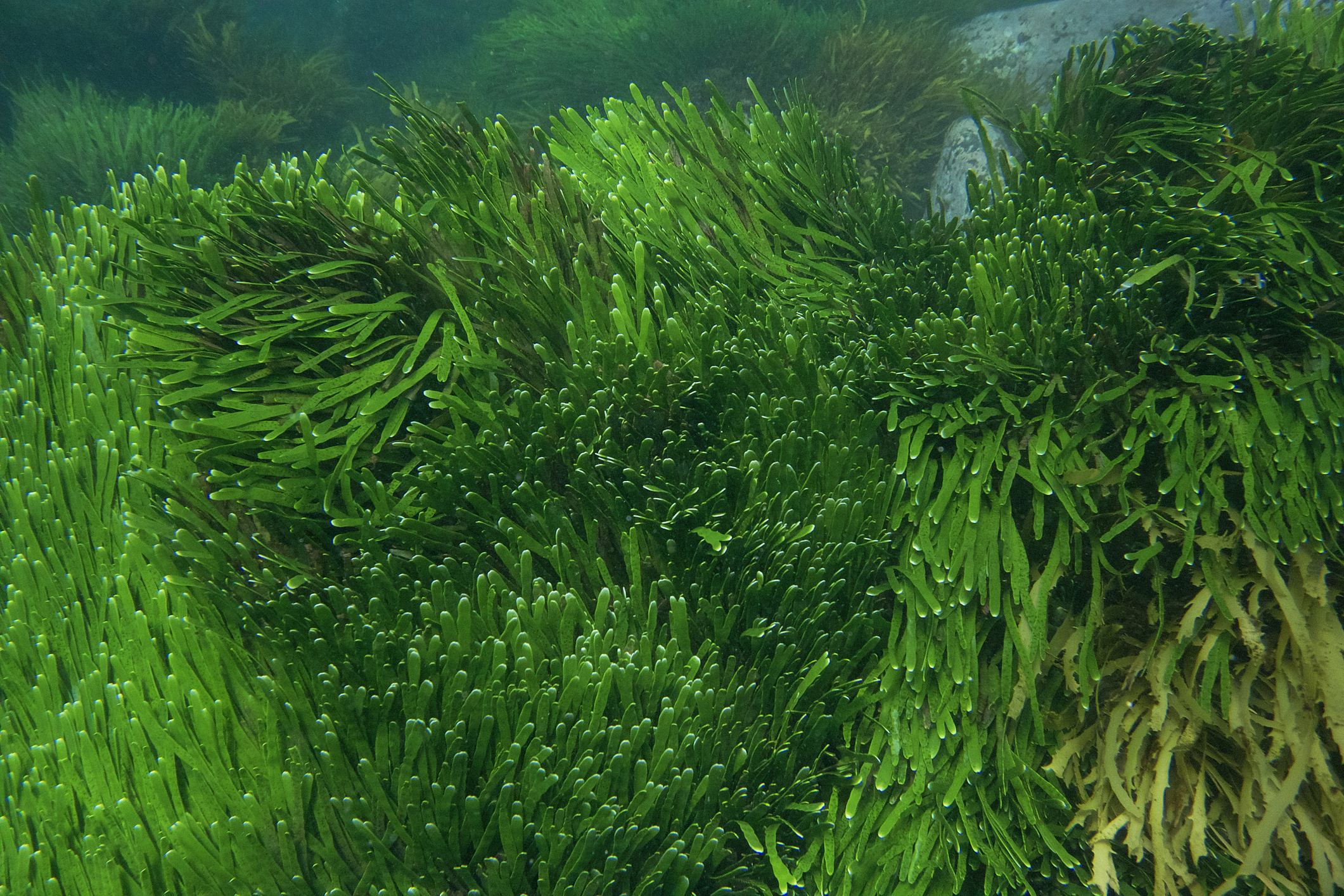

“Ocean bound” is plastic located within 50km from shoreline where waste management is insufficient. Improvements in collection infrastructure and anti-litter campaigns can reduce the volume of material that would be at-risk of entering the ocean and other waterways. Plastics manufacturers have been able to use ocean bound plastic as recycled content in new products.

While preventing plastic from entering the environment in the future is essential, recovering ocean plastic is also critical to improve existing ecosystems. Efforts to capture ocean plastic are more diverse than ever and range from large-scale efforts like the Ocean Cleanup, which develops and scales technologies to recover material from the oceans’ biggest gyres, to initiatives like the Ocean Plastics Recovery Project that send targeted expeditions to capture plastic from remote Alaskan coastlines. Technologies also exist to help capture plastic from waterways prior to entry into the ocean.

While recovered ocean plastic isn’t fit for all uses, due to degradation in the environment, industry is increasingly crafting ways to effectively recycle the material and use it in new products.

Litter cleanups are a commonly held volunteer activity, with non-profit organizations, schools, companies (including those within the plastics industry) dedicated to hosting cleanups in their communities.

In some areas, informal waste picking is the only source of waste collection available. “Waste pickers” who do this work will be paid to collect litter by hand and bring it to reclaimers to sell or reprocess into new products.